Process

-

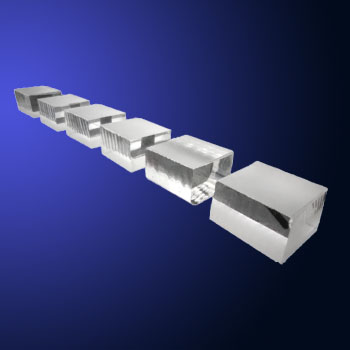

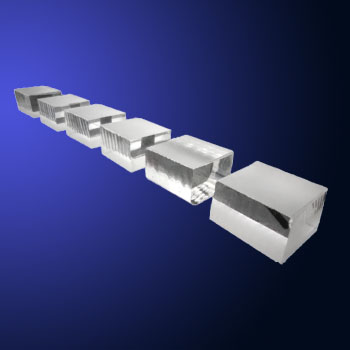

Supply Raw Materials

This process supply raw materials for glass in kilograms and follow intended raw materials thickness. After that, the materials will be measured in actual size to decide how to cut it so that it could fit customers requirement.

-

Multiple Cutting

Multiple Cutting is a process to cut block of glasses into gob shape based on decided dimension for pressing lens.

-

Separation

After Multiple Cutting process, the gobs will be separated by it weight range in grams to easily manage at the next process.

-

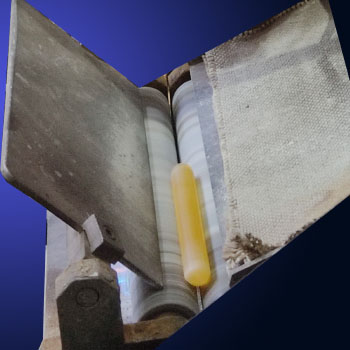

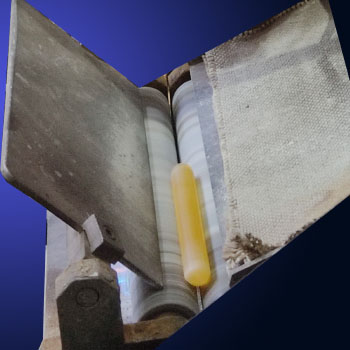

Barrel

Barrel is a process to remove sharp surfaces from the gob and to reduce the gob weight to meet product specification weight. Besides, this process can helps to reduce product's defect in the next process.

-

Reheat Press

Pressing process is a process to form the gobs into optical lens by using reheat and pressing with specific moulding based on customers requirement.

-

Annealing

This process is to remove stress from optical lens and adjust refractive index into desired specification.

-

Inspection

This process examines products, test pieces and UV inspection. This process is to eliminate various defects or nonconfirming to flow out.

-

Refractive Index

This process is to measure the refractive index of optical glass and make sure it is within the glass specification. Only optical glass within the specification are allowed to transfer to finish goods warehouse and ready for shipment.

-

Supply Raw Materials

This process supply raw materials for glass in kilograms and follow intended raw materials thickness. After that, the materials will be measured in actual size to decide how to cut it so that it could fit customers requirement.

-

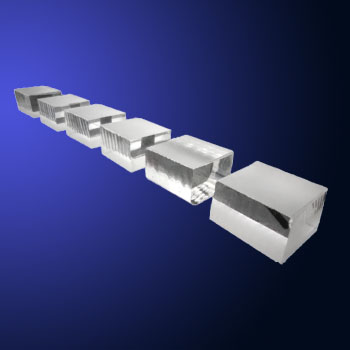

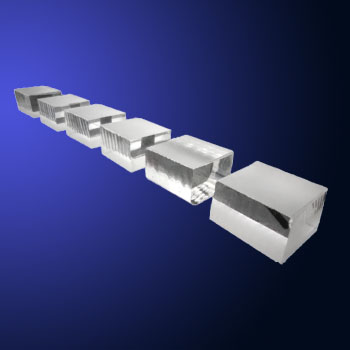

Multiple Cutting

Multiple Cutting is a process to cut block of glasses into gob shape based on decided dimension for pressing lens.

-

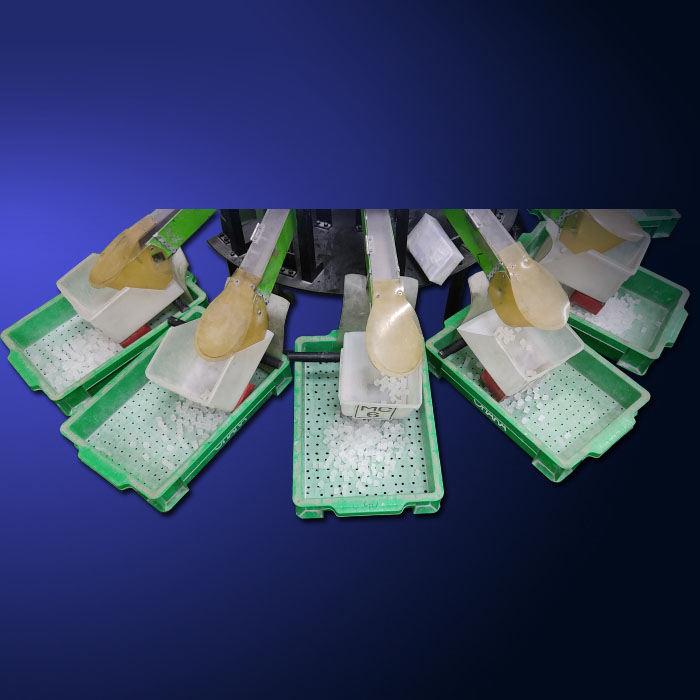

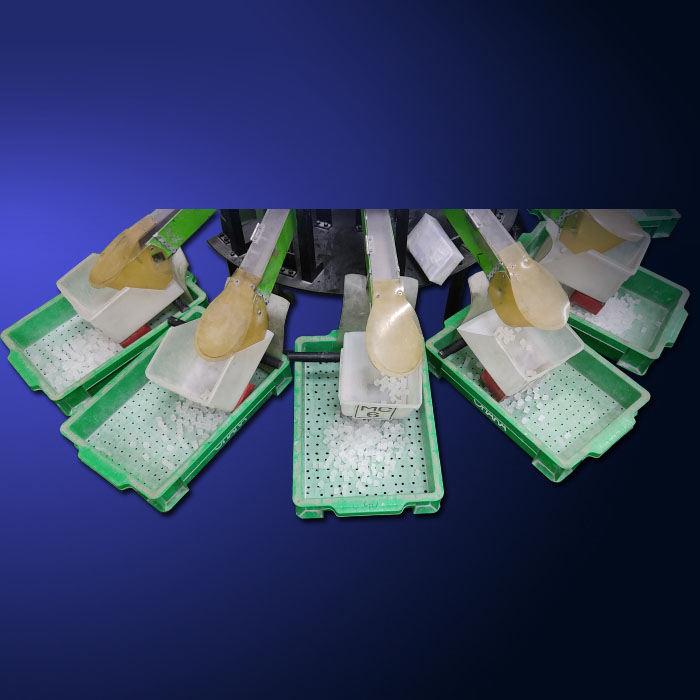

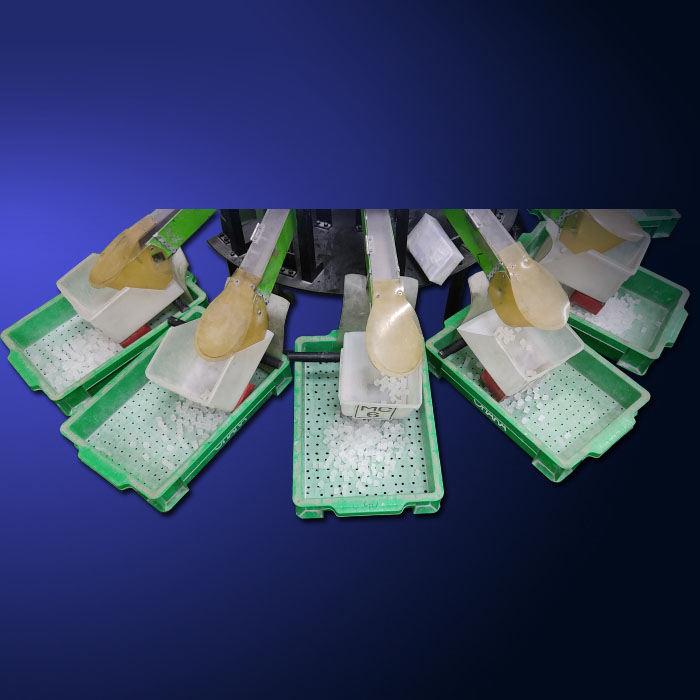

Separation

After Multiple Cutting process, the gobs will be separated by it weight range in grams to easily manage at the next process.

-

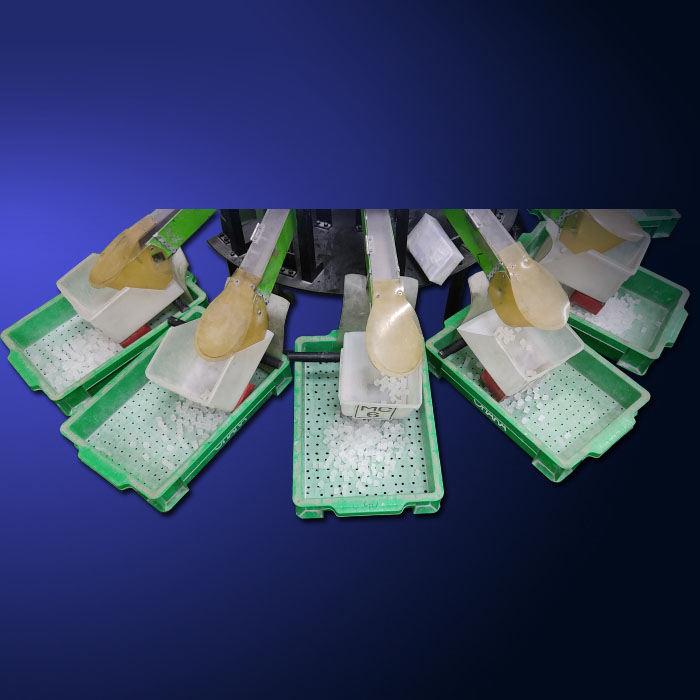

Barrel

Barrel is a process to remove sharp surfaces from the gob and to reduce the gob weight to meet product specification weight. Besides, this process can helps to reduce product's defect in the next process.

-

Reheat Roller Press

Pressing process is a process to form the gobs into long bar by using reheat and rounding based on customers requirement.

-

Annealing

This process is to remove stress from optical lens and adjust refractive index into desired specification.

-

Centerless

Centerless is a process to reduce the diameter, surface defects, or uneven by grinding the surface of long bars into the product's diameter specification.

-

Slicing

After centerless, the long bars will be placed on a jig with almost identical length then will be slice into pieces based on product's center thickness.

-

Inspection

This process examines products, test pieces and UV inspection. This process is to eliminate various defects or nonconfirming to flow out.

-

Refractive Index

This process is to measure the refractive index of optical glass and make sure it is within the glass specification. Only optical glass within the specification are allowed to transfer to finish goods warehouse and ready for shipment.

-

Supply Raw Materials

This process supply raw materials for glass in kilograms and follow intended raw materials thickness. After that, the materials will be measured in actual size to decide how to cut it so that it could fit customers requirement.

-

Multiple Cutting

Multiple Cutting is a process to cut block of glasses into gob shape based on decided dimension for pressing lens.

-

Separation

After Multiple Cutting process, the gobs will be separated by it weight range in grams to easily manage at the next process.

-

Barrel

Barrel is a process to remove sharp surfaces from the gob and to reduce the gob weight to meet product specification weight. Besides, this process can helps to reduce product's defect in the next process.

-

Reheat Roller Press

Pressing process is a process to form the gobs into long bar by using reheat and rounding based on customers requirement.

-

Annealing

This process is to remove stress from optical lens and adjust refractive index into desired specification.

-

Centerless

Centerless is a process to reduce the diameter, surface defects, or uneven by grinding the surface of long bars into the product's diameter specification.

-

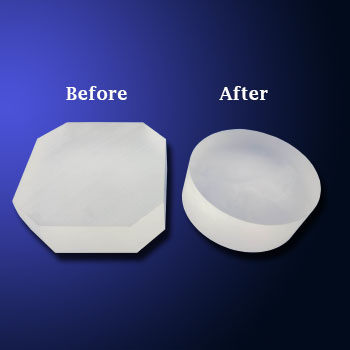

Ball Lens

After centerless, the long bar will be cut and grind to form ball shapes. Our precise and accurate machines will ensure higher yields production for ball lens resulting in competitive pricing for our ball lens.

-

Inspection

This process examines products, test pieces and UV inspection. This process is to eliminate various defects or nonconfirming to flow out.

-

Refractive Index

This process is to measure the refractive index of optical glass and make sure it is within the glass specification. Only optical glass within the specification are allowed to transfer to finish goods warehouse and ready for shipment.

-

Supply Raw Materials

This process supply raw materials for glass in kilograms and follow intended raw materials thickness. After that, the materials will be measured in actual size to decide how to cut it so that it could fit customers requirement.

-

Multiple Cutting

Multiple Cutting is a process to cut block of glasses into gob shape based on decided dimension for pressing lens.

-

Separation

After Multiple Cutting process, the gobs will be separated by it weight range in grams to easily manage at the next process.

-

Barrel

Barrel is a process to remove sharp surfaces from the gob and to reduce the gob weight to meet product specification weight. Besides, this process can helps to reduce product's defect in the next process.

-

Reheat Press

Pressing process is a process to form the gobs into optical lens by using reheat and pressing with specific moulding based on customers requirement.

-

Annealing

This process is to remove stress from optical lens and adjust refractive index into desired specification.

-

Rough Inspection

This process is to examines and eliminate defects from flow to next process.

-

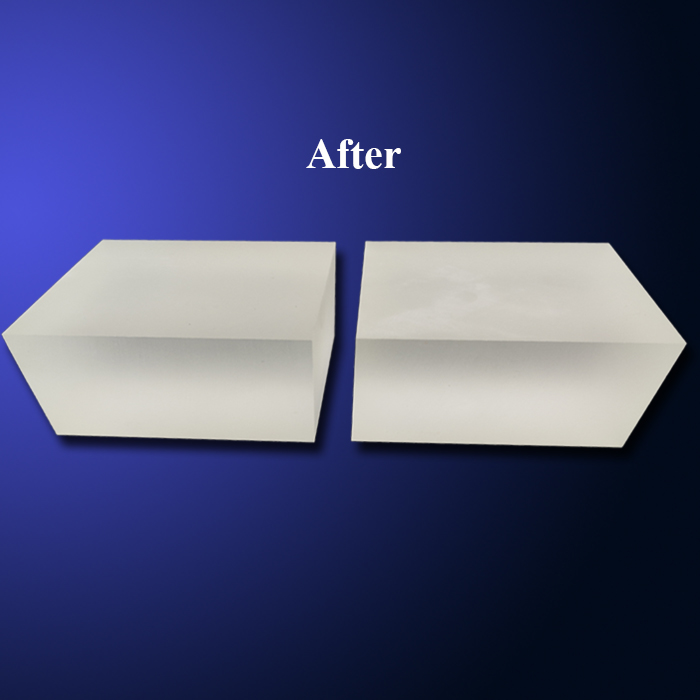

Curve Generator

Curve Generator process is to grind and smoothen the surfaces of optical lens. This process will form the lens into the desired shapes and dimension.

-

Inspection

This process examines products, test pieces and UV inspection. This process is to eliminate various defects or nonconfirming to flow out.

-

Refractive Index

This process is to measure the refractive index of optical glass and make sure it is within the glass specification. Only optical glass within the specification are allowed to transfer to finish goods warehouse and ready for shipment.

-

Supply Raw Materials

This process supply raw materials for glass in kilograms and follow intended raw materials thickness. After that, the materials will be measured in actual size to decide how to cut it so that it could fit customers requirement.

-

Multiple Cutting / Core Drill

Multiple Cutting is a process to cut block of glasses into gob shape based on decided dimension for pressing lens. While, Core Drill is a process to drill down block of glasses based on the cup's diameter.

-

Grinding / Lapping

Lapping process is to flatten the surfaces of gob / block by grind with abrasive. This process can achieve tight tolerances of flatness, parallelism, thickness or finish.

-

Centerless / Rounding

This process will grind edges of diameter to meet product requirement by rotating method.

-

Chamfering

This process is to reduce defects happening at the edges of optical glass by making a small cut, usually at a 45 degree angle.

-

Inspection

This process examines products, test pieces and UV inspection. This process is to eliminate various defects or nonconfirming to flow out.

-

Refractive Index

This process is to measure the refractive index of optical glass and make sure it is within the glass specification. Only optical glass within the specification are allowed to transfer to finish goods warehouse and ready for shipment.